DESIGN

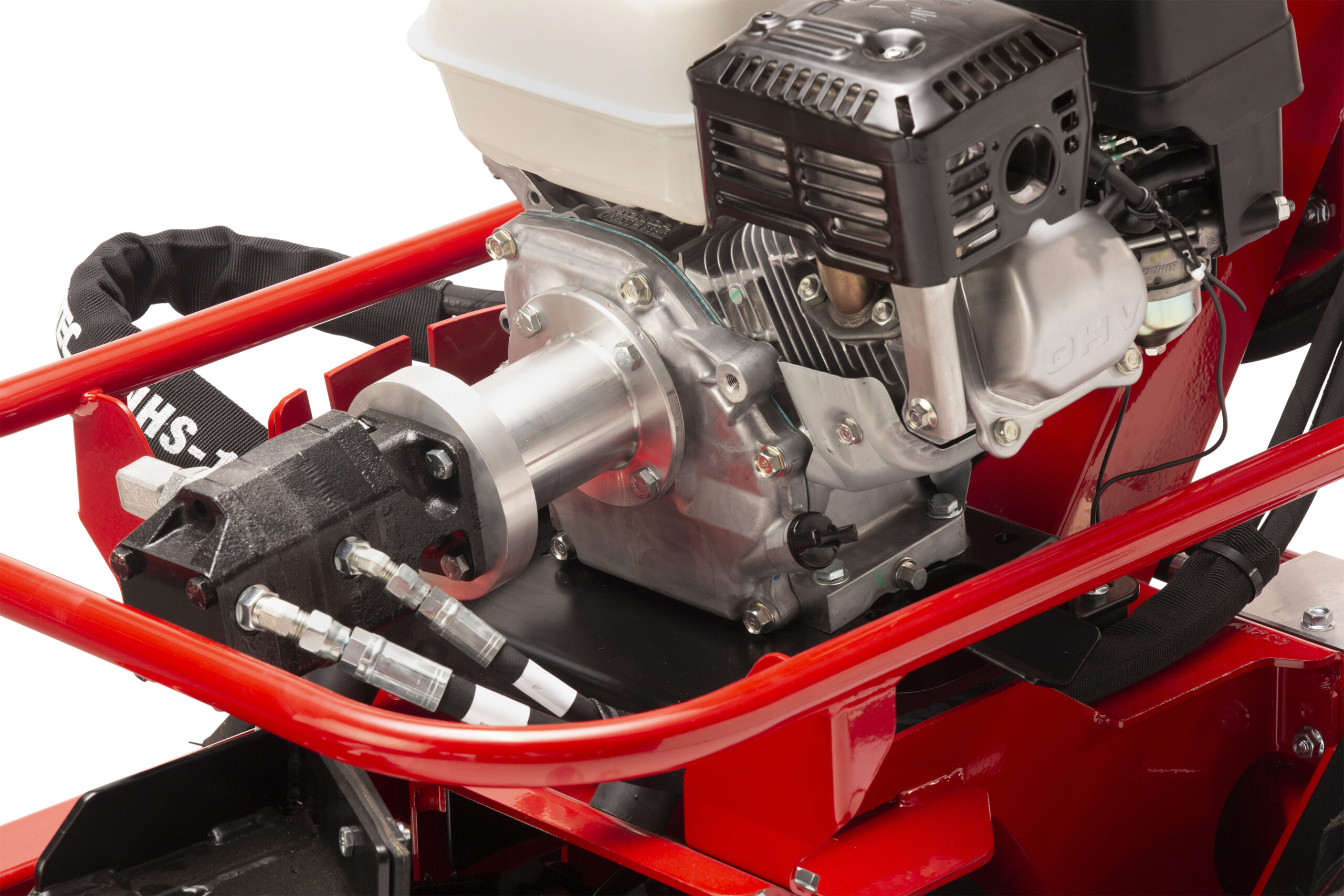

The 712MTH micro trencher features a unique automatic wheel drive propulsion system. This trencher utilizes a load sensing hydraulic valve to adjust the trenching wheel speed to the load on the digging chain. When the load on the digging chain increases, the sensing valve sends less oil to the wheel drive motor and the wheel speed will automatically slow down. When the load on the digging chain decreases, the sensing valve sends more oil to the wheel drive motor and the wheel drive speed will automatically increase. This keeps a constant load on the engine, regardless of the depth of cut or differing soil conditions. Not only does this help the trencher run at optimal efficiency, it reduces stress on the components, increasing their longevity.

CONTROLS

The automatic adjustment to the wheel speed eliminates the responsibility on the operator to constantly adjust their wheel speed. Nothing could be easier for the novice user. One control lever operates the wheel drive, and one lever operates the chain drive. After engaging the chain drive lever, the operator just engages the wheel drive lever and lets the trencher do the work. When the wheel drive is in forward, the chain drive will not activate, eliminating costly repairs sometimes caused by inexperienced operators.

ROI

Small trenchers can become one of your leading revenue sources. With a unique design that provides limited need for maintenance and repair, the 712MTH will keep going out into the field time and again without sitting in the shop waiting for repair.